The selection of an eye cream OEM manufacturer is key to a brand’s success. Back in 2018, a fledgling brand chose the wrong OEM partner, which led to a full recall of its eye cream just three months after launch due to emulsification issues—resulting in a multi-million-dollar loss. Today, the global eye cream market has exceeded $40 billion in size. Choosing the right eye cream OEM manufacturer is not only about product quality, but also determines the speed of market response and cost control capabilities. This article provides an in-depth analysis of the world’s top eye cream OEM manufacturers, helping you gain a competitive edge in the track of functional products.

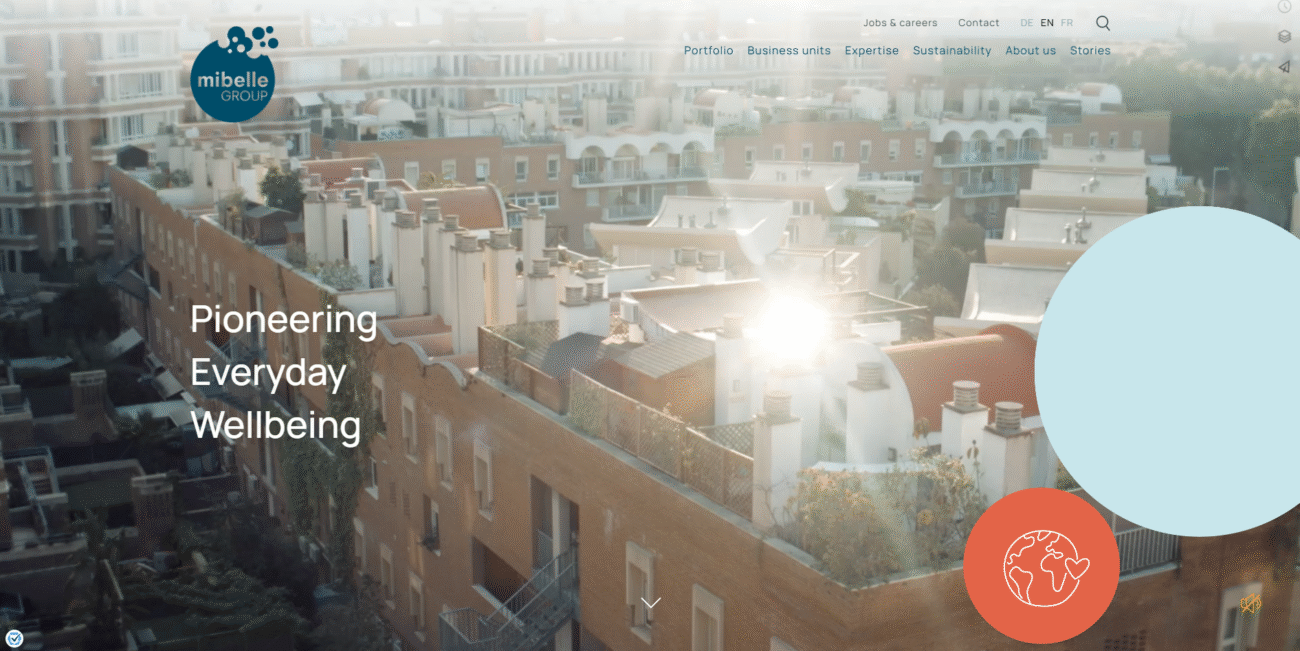

| Manufacturer Name | Advantages | Product Focus | MOQ | Applicable Brand Types |

| COSMAX | Global Top 3 OEM Factories with Complete International Certifications | High-End Functional Eye Cream | 50,000 units | International Premium Brands, High-End Chains |

| Intercos | Leading in “Makeup-Skincare Integration” Technology | Brightening Eye Cream, Concealing Eye Cream | 5,000 units | Color Cosmetics Brands, Light Luxury Positioning |

| DESIFINE | Innovation in the Application of Bioactive Ingredients | Botox-Like Eye Cream, Anti-Aging Eye Cream | 3,000 units | Cross-Border E-Commerce, Emerging Brands |

| Toyo Beauty | Leading in Nanocarrier Technology | Whitening Eye Cream, Anti-Aging Eye Cream | 3,000 units | Cosmeceutical Brands |

| Mibelle | Plant Stem Cell Extraction Technology | Organic Eye Cream, Sensitive Skin Eye Cream | 2,000 units | Organic Brands, High-End SPAs |

1.COSMAX

Founded in South Korea in 1992, the company has 23 factories across 7 countries worldwide, with an annual production capacity of 1.53 billion units and 2024 sales revenue of RMB 11.449 billion. As one of the world’s Top 3 cosmetics OEM (Original Equipment Manufacturing) factories, it holds complete international certifications and owns 320 patents.

Production Capacity

The factories in Shanghai and Guangzhou are equipped with automated production lines, boasting a daily production capacity of 30 million facial masks and an annual production capacity of 500 million color cosmetics products. They have obtained ISO 22716 and GMPC certifications.

Technological Advantages

The BioDeliver® glycolipid liposome penetration technology (certified by IFSCC) enables niacinamide penetration to reach 1.86 times that of conventional liposomes. Additionally, the company possesses anti-aging microbial exosome raw materials, a 6D Collagen targeted delivery system, and an AI-modified manganese superoxide dismutase, which has been certified by international journals.

Product Range

- High-End Functional Eye Cream

- Essence

- Facial Cream

- Lip Gloss

- Foundation

Cooperative Brand Cases

International brands such as L’Oréal and Estée Lauder, as well as domestic brands like Florasis and Perfect Diary, have all collaborated with Cosmax. As a professional eye cream OEM manufacturer, Cosmax provides high-quality OEM services for numerous well-known brands.

2.Intercos

Founded in Milan, Italy in 1972, the company has 13 production bases across 9 countries worldwide. Its Suzhou Smart Manufacturing Base was launched in 2025. As a cosmetics OEM enterprise leading in “Makeup-Skincare Integration” technology, it serves numerous internationally renowned brands.

Production Capacity

Equipped with advanced automated powder compaction equipment for color cosmetics, it has a daily production capacity of 100,000 face powder compacts. The filling accuracy of lipsticks reaches ±0.01g, and the annual production capacity amounts to hundreds of millions of units, meeting the needs of large-scale production.

Technological Advantages

The patented PRISMA powder technology enables 30% pearlescent raw materials to achieve high color development. The biomimetic technology realizes 8-hour long-wearing makeup through the lotus leaf effect. It also masters plant stem cell extraction (citrus embryo primary cells) and octopus-like color powder coating technology. Additionally, its microbiome skincare solutions have obtained Ecocert certification.

Product Range

- Brightening Eye Cream

- Concealing Eye Cream

- Eyeshadow

- Lipstick

- Swiss CRB Anti-Aging Skincare Products

Cooperative Brand Cases

International brands such as Dior and Armani, as well as domestic brands like CHANDO and Mao Geping, have all chosen Intercos as their cooperative partner. Its OEM strength in the fields of color cosmetics and skincare is widely recognized.

3.DESIFINE

Founded in 2000, DESIFINE was established under the leadership of Rolf Lentfer, a German engineer with 45 years of experience. Its Foshan base is equipped with German IKA emulsification equipment, and it has jointly built a peptide R&D laboratory with Jiangnan University. As an emerging and cutting-edge eye cream OEM manufacturer that has risen in recent years, DESIFINE focuses on the research of bioactive ingredient applications.

Production Capacity

The Foshan factory covers an area of 9,000 square meters, with a Class 100,000 clean workshop equipped with advanced emulsification equipment. It has a daily production capacity of 150,000 eye cream units and supports small-batch customization.

Technological Advantages

Led by Rolf Lentfer, the German engineer with 45 years of experience, DESIFINE excels in recombinant collagen and peptide compounding technology. It holds 11 cosmetics patents, covering recombinant collagen and Botox-like Hexapeptide-8 encapsulation technology. The activity retention rate of its freeze-dried powder reaches 98%, and the transdermal absorption rate within 48 hours is increased by 2.3 times.

Product Range

- Botox-Like Eye Cream

- Recombinant Collagen Eye Cream

- Peptide Anti-Wrinkle Eye Cream

- Overnight Repair Eye Cream

- Eye Cream for Sensitive Skin

Cooperative Brand Cases

DESIFINE serves chain channels such as Watsons, Walmart, and MINISO. The “Botox-Like Eye Cream” developed by the company leads in sales on cross-border e-commerce platforms, demonstrating DESIFINE’s innovative strength as a professional eye cream OEM manufacturer.

4.Toyo Beauty

Founded in 1985, it is a top-tier cosmetics OEM enterprise in Japan and a joint R&D base with the University of Tokyo. It has focused on nanocarrier technology for 38 years, exclusively supplies the core ingredients of Shiseido Red Anessa Eye Cream, and has obtained the Functional Claims Certification from Japan’s Ministry of Health, Labour and Welfare. It serves brands such as Shiseido and DHC.

Production Capacity

The Tokyo factory is equipped with 8 production lines, with an annual production capacity of 120 million units. It has obtained ISO 22716 certification and certification from Japan’s Ministry of Health, Labour and Welfare.

Technological Advantages

It owns exclusive nano-microcapsule encapsulation technology; the particle size of nano-companion carriers ranges from 20 to 40 nm, and the transdermal efficiency is 3 times higher than that of traditional liposomes. The patented “resveratrol glycoside” encapsulation technology increases the stability of active ingredients by 42%, and the technology has obtained international certification.

Product Range

- Nano Whitening Eye Cream

- Coenzyme Q10 Anti-Aging Eye Cream

- Multi-Effect Repair Eye Cream

- Eye Essence

- Cosmeceutical Eye Cream

Cooperative Brand Cases

It provides core technical support for Shiseido Red Anessa Eye Cream and acts as the OEM manufacturer for DHC Firming Eye Cream.

5.Mibelle

Founded in Zurich in 1954, it is a global leader in organic cosmetics OEM. Its Alpine Plant Research Center houses a bank of over 200 rare plant stem cell varieties, exclusively supplies raw materials to La Prairie, and has obtained the EU ECOCERT Organic Certification. It also owns the Alpine Plant Research Center.

Production Capacity

It has 3 organically certified factories with an annual production capacity of 80 million units, and its production is powered entirely by 100% renewable energy.

Technological Advantages

Its patented PhytoCellTec™ plant stem cell technology cultivates callus through wound induction. Alpine rose stem cells increase the survival rate of skin stem cells damaged by UV radiation by 42%. Its liposome encapsulation technology has obtained patents in the United States and South Korea. The company holds dual organic certifications (Ecocert and Cosmos) and operates a cruelty-free production system.

Product Range

- Organic Plant Stem Cell Eye Cream

- Alpine Herbal Repair Eye Cream

- Additive-Free Eye Cream for Sensitive Skin

- Anti-Pollution Protective Eye Cream

- Firming & Lifting Eye Cream

Cooperative Brand Cases

It is the technical cooperation partner for L’Occitane Immortelle Eye Cream and the OEM manufacturer for Aesop Eye Serum.

6.FAQs

How to Evaluate the R&D Capabilities of an Eye Cream OEM Manufacturer?

Evaluate the scale of the R&D team (it is recommended to choose a team with more than 15 members), laboratory certifications (priority should be given to CNAS certification), the number of patents (at least 5 or more relevant patents), and the speed of formula updates (no fewer than 2 new products per month). As professional eye cream OEM manufacturers, enterprises such as Mingyu Cosmetics all meet these standards.

What Certifications Are Required for OEM Manufacturing of Functional Eye Creams?

Basic certifications include GMPC and ISO 22716. For products with specific efficacy such as anti-wrinkle, third-party test reports (e.g., SGS efficacy verification) are required. For export to the EU, CPNP filing must be completed. Formal eye cream OEM manufacturers will assist in completing the full certification process.

How to Control the OEM Cost of Eye Creams?

Choose modular formula design (to reduce R&D costs), share packaging material molds (to reduce mold opening costs), and arrange production batches reasonably (to lower the minimum order quantity). Establishing long-term cooperation with an eye cream OEM manufacturer usually enables a 5-10% cost discount.

What Are the Key Points of Quality Control in Eye Cream OEM Manufacturing?

Incoming raw material inspection (focusing on the content of active ingredients), emulsification temperature control (with an accuracy of ±2℃), filling cleanliness (Class 100,000 or higher), and finished product stability testing (6 months under 45℃ conditions). Professional eye cream OEM manufacturers will provide full-process quality control reports.

What is the general lead time for eye cream OEM manufacturing?

The lead time is 25-30 days for conventional products, 35-45 days for functional products, and 50-60 days for products requiring special packaging materials. Choosing an eye cream OEM manufacturer with its own packaging material factory can shorten the lead time by 15%.